|

|

|

|

|

L.A.T introduces the Re-Vial-utionary

new FLASH Vial and Labware Processing System.

easyFLASHvial®,

Flexible-Lab-

Automation-System-

Handler, It’s Re-Vial-utionary!

Versatile–Feeding, labeling,

filling, capping, inspection…“all-in-one”

Compact–Many functions

in one, miniature robotic cell

Large Capacity–Bulk feeders

and tray stackers for unattended use

Fast–High-speed robotics/parallel

operations for high throughput

Accurate–Sensor/vision

feedback and precision robotics

Reliable–Constructed

of industrial, production-proven components

Simple–Intuitive easyFLASH"Windows

-style” software

Flexible–“Smart”

system with reader, sensor and vision feedback

Adaptable–Vials, caps,

bottles , tubes, syringes , various labware…

It’s Re-Vial-utionary! L.A.T introduces the Re-Vial-utionary

new FLASH Vial and Labware

Processing System. This cutting-edge design combines accuracy,

reliability and space

savings at a low price per operation performed within the

system. How do we do it?

The FLASH utilizes flexible robots controlled by sheadFLASH-Software,

our highly

adaptable and easy to use control software. sheadFLASH Software

interfaces with

customer LIMS, Database and Network systems and merges the

information with its

internal system control. Data tracking, marking, print inspection/verification

and

other operations are seemlessly integrated and transparent

to the operator.

“Smart” real-time flexibility allows the system

to adapt to sensor input, logging

data each step of the way. The Xantus liquidhandling robot

achieves unsurpassed

accuracy, flexibility and reliability. The robot enables

a range of capabilities such

as pick and place handling, capping/uncapping, wrap around

labeling/printing

(while spinning vials), filling, weighing, inspection, packaging

and more. The

result…..rapid throughput, cutting-edge design combines

accuracy, reliability

and space savings at a low price per operation performed

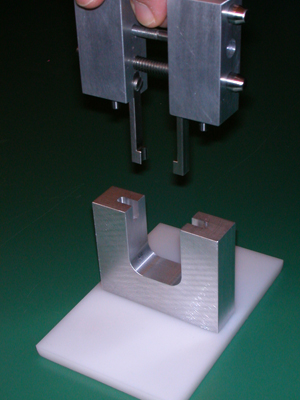

Tube handling / gripper tools for all kind of tubes and

plates.

Broad Ranging Features (Standard

and Optional)

- Input (Tray/Bulk/Conveyor)

- Output (Tray/Bulk/Package/Envelope)

- Long-Term Run Storage

- Various Printing Options (Thermal

Transfer Labeling/Inkjet Printing/Pad/Laser)

- Controlled Environment (Cleanroom/Thermal)

- Sterile/Aseptic (Stainless Steel)

- Advanced System Integration (Mass

Spec., Readers, Washers, Pipettors, Incubators, Storage

& Retrieval Systems, Scales…)

- Database Management LIMS/Network/Scheduler

Compatible

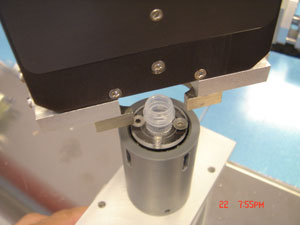

- Capping/Uncapping

- Dispensing/Filling

- Machine Vision Inspection/Verification

- Barcodereading one or 2D codes.

- and more

Tube capper/decapper

Put barcode on tubes and vials automatic with robotic tube

gripper

|

|