dispEASY

Highend Benchtop StandAlone Disperser/Homogenisator

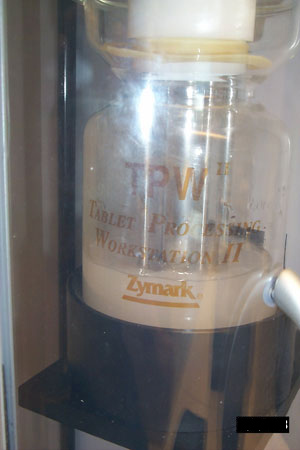

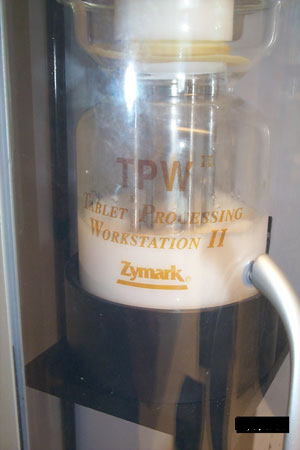

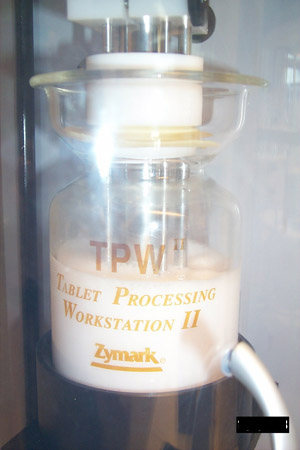

TPWII

workstation

The

SAD/SAH Homogenizer

Extraction Module

The dispEASY module is a stand-alone version of the

TPWII homogenization module that provides all the

control and functionality in the TPWII >=v2.0 software.

TPWII

workstation

General information:

• Same dispersion parameters provided on TPW

II software v2.0 and greater.

o Speed (20 K rpm)

o Pulses

o Pulse Time (sec)

o Large tablet clearance

o Large tablet parameters

o Vessel cycling

• Same hardware used on TPW II

o Homogenizer

o Probe with vessel plug

o Sampling cannula

o Elevator or other device to simulate large tablet

operation and vessel cycling

o TPW II extraction vessel

• Parameters will have same boundaries as provided

in TPW II software.

• Direct computer control with a simple instrument

control screen that does not require 21 CFR part 11

compliance.

• Dispersion parameters can be entered and executed.

It is also possible to recall stored methods if you

are allowed to by password.

• Password security on applications and method.

• Easy vessel access for placing vessels into

and out of homogenizer.

• Protective shield around vessel and probe

during operation.

• Probe washing by “clean vessel”

or manual cleaning.

• Abort function located on Homogenizer and

software screen

• Mechanism to prevent operation of the equipment

when vessel and safety shield are not in place.

• Beep when complete

Software Requirements

• In order to comply with 21 CFR part 11, PC

control will not be available.

• All operating parameters will be input via

a touchscreen and the embedded controller.

• Methods can be stored and resued if the operator

has the right password.

• Optional direct printing of method parameters

and probe speed via printer port.

Hardware Requirements

• TPWII Homogenizer

• TPW II Probe and vessel seal

• TPW II Extraction vessel

• Safety shield with lockout to prevent use

without vessel and shield in place.

• Sampling cannula

• Mechanism for large tablet clearance and cycling.

(Elevator & Stepper)

Regulatory / Agency Requirements:

• CE, CSA, FCC

• IQ, OQ, PQ Document set for user validation

Unit package inclueds:

• SAD/SAH. Includes dispersion unit, 2 TPW II

Extraction Vessels, IQ/OQ Validation Document, and

software.

Size:

300*400*800mm (W,L,H)

• Does not exceed height, length and width of

current homogenizer with TPW II extraction sidecar.

Additional information:

Electrical:

• VA(max) 800VA

• Supply 100 VAC +/- 10%, 50-60Hz

120 VAC +/- 10%, 50-60Hz

230 VAC +/- 10%, 50-60Hz

240 VAC +/- 10%, 50-60Hz

Noise:

• Less than 70 dB under the following conditions:

1. All shields are secure in operating position

2. 20,000 rpm in 250ml water

3. homogenizer probe height is at zero

Performance:

• Speed 2,000 – 20,000 rpm +/- 10%

(30mm generator in 500ml water)

(10 second minimum pulse time)

Capacity:

• One Custom vessel, 50 – 500ml, TPWII

compatible

• Available clear or tinted for photosensitivity.

Safety:

• Meets requirements of CE Low Voltage Directive

• Includes:

Vessel Safety Shield

Safety Shield Lock-out switch

Minimum safe volume sensor/switch

5000 RPM

8000 RPM

10.000 RPM

Ready, soak and settle.

|